Pcb size

50-450mm(w)

Preheating Zone

Power:16KW Length:(1800mm 4sections PID control

Solder temperature

9KW

(Room temperature -300℃)

SMT wave soldering machine PCBA

Features

◆Windows7 operating system, Chinese and English interface switch, easy to operate.

◆Fault diagnosis function, can display each fault, display and store in automatic alarm list

◆Control procedures can automatically generate and backup the data report, easy to ISO 9000

management

◆Automatic board access device, smooth and stable.

◆Specially hardened aluminium guide rail with high hardness and strength, guarantees no deformation at

high temperature

◆4mm SUS316L imported stainless steel furnaces, new design, beautiful appearance

◆Wave automatically when board through,adjustable peak width to minimize tin oxidation

◆600mm extended two-section preheating, infrared independent PID temperature control, uniform

heating, safe and stable.

Product Paramenters

Part list

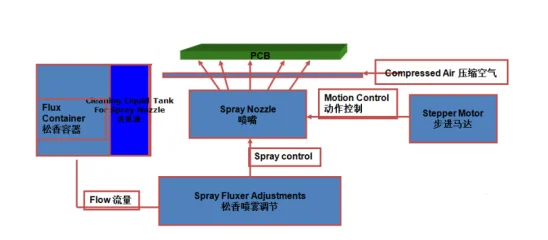

Spry System

◆With Lumina (Japan) nozzle, the spray range is20-65mm, the nozzle height is 50-80mm, and the maximum flow rate is 60ml/min.

◆Uses AirTAC (Taiwan) filter, pointer gauge shows air pressure, all spray system pipes are acid and alkali resistant corrosion protection pipes.

◆Spraying system adopts scanning spraying method, limit switch and entry eyesight are combined to control, and PCB is

automatically detected by inductive spraying according to the speed and width of PCB, so that the wetting range of flux can achieve the best effect. Inlet spray head and stepping motor are efficient, stable and reliable.

◆Stainless steel bent forming tray is used underneath the spray head for loading wastewater and flux, which can be extracted and cleaned at will.

◆The air extraction system is a superimposed automatic recovery system with three layers of stainless steel wire mesh filtration to minimize residual flux blockage in the air extraction pipeline by utilizing the fluid characteristics to filter excess flux.

◆Pneumatic air knife, which blows excess flux during spraying into the recovery tank to prevent flux from entering the preheating zone and ensure production safety.

◆All stainless steel + aluminium alloy support, easy cleaning and maintenance, strong corrosion resistance, durable.

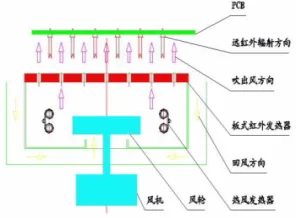

"Far Infrared + Hot Air" Composite Heating Principle

◆Porous plate heater is used as the infrared heating source and the far infrared light penetration is used to

directly heat the PCB , thus avoiding the problem of insufficient heating capacity in traditional full hot air

mode.

◆Composite heating, mainly by infrared heating, supplemented by hot air convection, can improve

heating capacity and uniform heating.

PREVIOUS:Dual Wave Soldering Machine 450 for LED driver with out spray

NEXT:Environment Friendly Wave Soldering Machine N250

Contact: Nancy

Phone: 13235536784

E-mail: [email protected]

Whatsapp:0086-13235536784

Add: No. 108 Fuyuan Street, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen

We chat