hanwha(formerly Samsung branded chip mounters acquired by hanwha) offers a full range of new/used chip mounters/place and pack machine

PCB loader

Technical Parameters | ||||

Model | 250A | 330A | 390A | 460A |

Dimensions | 1360x765x1200mm | 1630x845x1200 | 1830x905x1200 | 1830x980x1300 |

PCB Board size | 50-250mm | 50-330 | 50-390 | 50-460 |

PCB Transport direction | L-R(left-right) | |||

Material frame specifications | 330x250x563mm | 450x330x563mm | 550x390x570mm | 550x460x570 |

Material rack lifting step | 10,20,30,40mm | |||

Working height | 900±20mm | |||

weight | 200kg | 230kg | 260kg | 280kg |

weight | PLC+touch screen | |||

Operating Voltage | AC220V/50-60HZ | |||

working pressure | ≥0.4MP | |||

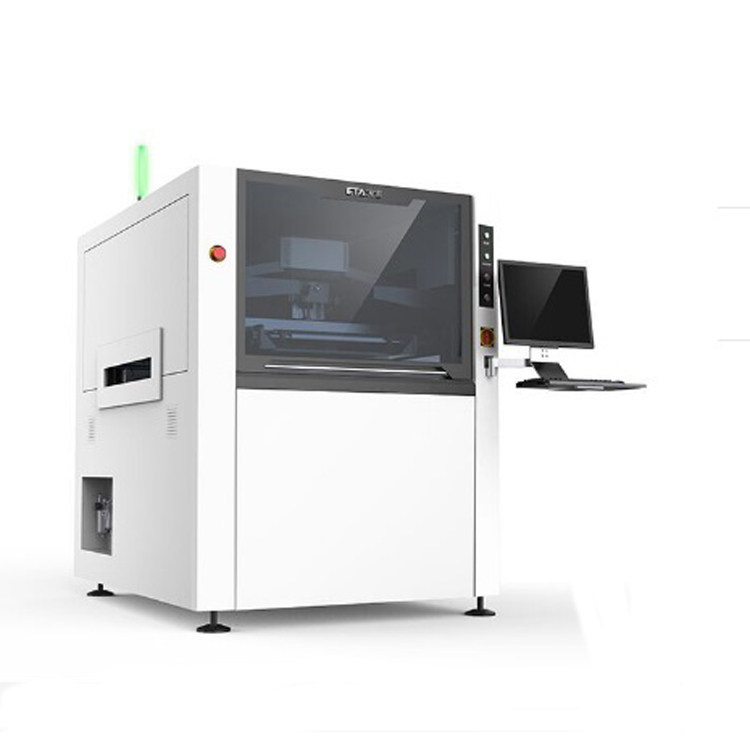

2.auto printing machine

A Seriel smt stencil printer is high accuracy and high stability of the fully automatic printing machine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Specification :

A Series High Precision Automatic solder paste printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~1200mm x 800mm;

PCB thickness: 0.4mm ~ 14mm

FPC thickness: ≦0.6mm (Excluding jig)

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,

min. ball 0.2mm;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

3. Samsung SM481 Pick and place machine.

Samsung SM481 Chip Mounter is based on the high-speed placement machine SM471 platform for the VISION system to

strengthen the same level of equipment in the fastest equipment,

It is equipped with a cantilever 10 shaft, the new flight camera and the application of the

best suction / placement action, so as to achieve the same level of products in the world as

fast as 39,000CPH. The other can correspond to a minimum of 0402 components to the

maximum □ 42mm IC, and increased practical productivity and mounting quality by applying

electric feeders, which can be shared with SM pneumatic feeders, thus maximizing

the customer's convenience of use.

4. high production Capacity reflow oven F10.

1. Well-known brand computer with PLC intelligent control system, high precision temperature control in ± 1-2 ℃ (if the computer has gone failure accidentally, it can realize off-line mode and not affecting production) and to ensure that the control system is stable and reliable;

2. Windows XP operating platform with user friendly operation.

3. In order to ensure safety and reliability, hood opening in automatically.

4. Device is equipped with mesh belt, transport smoothly, no shaking and no deformation, which ensure smooth PCB transport. Synchronous guide transmission mechanism and SMEMA connection ensure that guide adjustable wide precision and high service life.

5. Automatic controlled chain lubrication system..

6. PID closed loop control for all heating zones independently, sequential start up to reduce power consumption)

7. Mesh/chain transmission controlled by computer, which can fulfil different kinds of PCB production criteria.

8. Visual & Audio Alarm for abnormal condition.

9. With leakage protector, ensure safety protection for operating personnel and control system.

10. The built-in UPS and automatic delay shutdown system guarantee power failure or overheat won’t harm the PCB and machine.

11. The German ERSA world leading tiny circulation heating mode, and the upper and lower independent air tiny circulation system, temperature uniformity and thermal compensation high efficiency, high efficient supercharged accelerated air duct, greatly improve the circulating hot air flow, heat up temperature quickly (about twenty minutes), thermal compensation for high efficiency, high temperature welding and curing;

12. The upper and lower every temperature zone with independent temperature inductive sensor, real-time monitoring and compensation every temperature zone balance;

13. Have password administration of the operating system, to prevent the irrelevant personnel changes to the process parameters, operation records management traceability process parameters modification, improve the management convenient. Capable for saving user existing parameters and profile printout;

5. unload machine

1)Machine Size(L*W*H):L2300*W980*H1200mm

2)Special Aluminum alloy guide rails and rubber belt

3)Magazine lifting with screw rod by 90W electric-brake motor which made in Taiwan

4)Pneumatic PCB clamping structure

5)Attach one set 0.7m length pcb conveyor

6)Magazine size(L*W*H): (L)535*(W)460*(H)565mm

7)PCB max size(L*W):(L)500*(W)390mm

8)Direction:R-L/L-R

9)Adjustable Lifting distance:10,20,30,and 40mm

10)Programmable Mitsubishi PLC and controller

11)PCB Automatic loading to conveyor

12)Operation Control system: Touch Panel controlled interface

13)Power: 220V 50HZ

14)Air pressure: 0.4-0.6MPa

15)the max store PCB Quantity:50pcs

16)One set Electronic control box

Contact: Nancy

Phone: 13235536784

E-mail: [email protected]

Whatsapp:0086-13235536784

Add: No. 108 Fuyuan Street, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen

We chat