Basic parameters:

Claws: New double hook claws, spring compression claws, D-40 duckbill claws, double hook claws.

Extraction method: Updraft + side draft.

Preheating method: Slightly hot air/infrared.

Number of preheating zones: 3.

Width range (mm): 50-350.

Transmission speed range (mm/min): 500-1800.

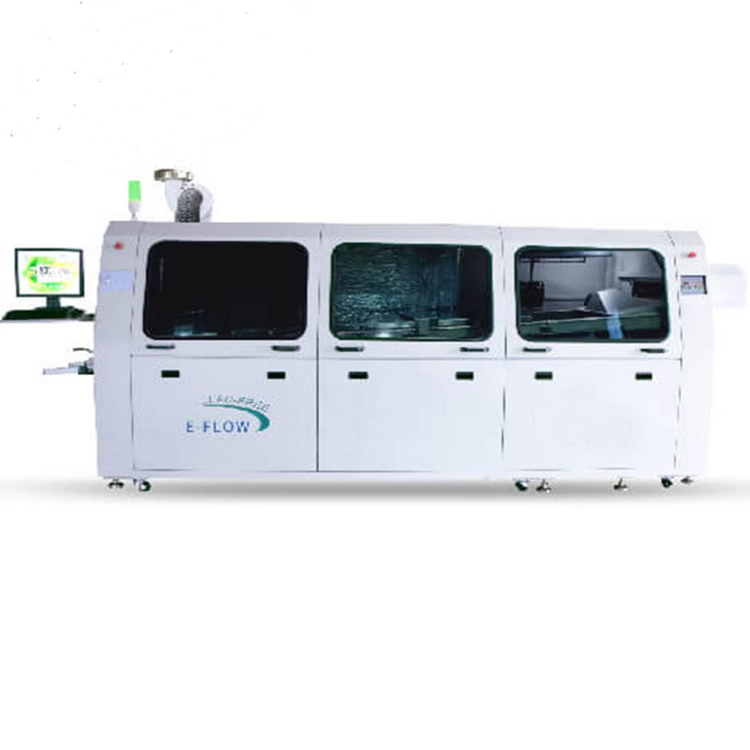

Wave soldering machine E-flow

Features:

● Transportation system:

It adopts a segmented floating structure to effectively prevent the deformation of the guide rail. The new titanium alloy double hook grip, non-stick tin, direct connection to the board connection.

● Spray system:

Unit integrated module design, spray moving part and spray gas, liquid, circuit control part are integrated, connected to the host through a quick connector, the nozzle uses a new type of precision nozzle, can achieve high efficiency, uniform spraying effect, can Meet the technological requirements of water flux.

● Preheating system:

The use of micro hot air + far infrared heating tube method, the heating is more uniform, three-stage preheating temperature zone, drawer modular design, flexible choice of mixed preheating mode. The temperature is even and stable.

● Forced natural air cooling system.

A

Basic parameters:

Claws: New double hook claws, spring compression claws, D-40 duckbill claws, double hook claws.

Extraction method: Updraft + side draft.

Preheating method: Slightly hot air/infrared.

Number of preheating zones: 3.

Width range (mm): 50-350.

Transmission speed range (mm/min): 500-1800.

Cooling method: strong cooling air, chiller.

Wave Soldering E-FLOW Left to Right 1 Red 2 Hot; Heavy Duty Double Gripper Transmission

1. Main features:

1. Connecting device:

Linkage into the board connection method, aluminum guide rail, stainless steel chain drive.

2. Transmission system:

Equipped with heavy-duty double hooks, aluminum alloy guide rail anti-deformation structure design; manual adjustment of substrate width; adjustable conveying angle, equipped with digital angle indicator; transport speed

Adopt frequency converter control, stepless speed regulation.

3. Tin furnace system:

The inner tank of the tin furnace is made of special cast iron material, and the surface is treated with anti-corrosion treatment; the direct-connected motor drives the wave peak, and the frequency conversion speed regulation; tin slag diversion and oxide reduction device; manual control

The tin-making furnace enters and exits and moves up and down; external heating device, PID temperature control method and low liquid level alarm.

4. Spray system:

Modular design, spray movement is controlled by stepper motor; corresponding to PCB spray length is automatically adjusted, digital setting of spray width and speed, with pressure gauge fine-tuning device adjustment

Control spray flow and spray particle size; constant pressure device supplies flux, flux level alarm and flux automatic addition; strong exhaust and filtration system;

Isolate the air knife between spraying and preheating.

5. Preheating system:

The new drawer-type modular and energy-saving design, one-stage infrared and two-stage micro-hot air circulation heating, higher thermal efficiency and more uniform temperature. Three-stage temperature zone, the length of the preheating zone is 1.8

Meter, PID temperature control mode.

6. Cooling system:

Forced natural wind up and down cooling.

7. Claw washing device:

Special brush for cleaning.

8. Control system:

PC+PLC electrical control system, Chinese and English window operation interface, data storage and other functions.

2. Technical parameters:

Substrate size: 50~350mm(W)*120mm(H)

Entry height: 750±20mm

Transmission speed: 500~1800mm/Min.

Teleportation angle: 4~7º

Transmission direction: left→right

Flux tank capacity: Approx.2L

Spray exhaust fan: 380V AC 750W.

Compressed air: 4~6Bar. 100L/min.

Preheating temperature: Max.200℃

Tin furnace temperature:Max.300℃

Tin furnace capacity: Approx.480Kg

Crest height: Approx.12mm

Dimensions: 4350(L)*1420(W)*1750(H)mm

Overall weight: Approx.1600Kg

Power supply: three-phase 380VAC 50Hz

Total power: Approx.33KW

Operating power: Approx.8KW

Contact: Nancy

Phone: 13235536784

E-mail: [email protected]

Whatsapp:0086-13235536784

Add: No. 108 Fuyuan Street, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen

We chat